prototyping

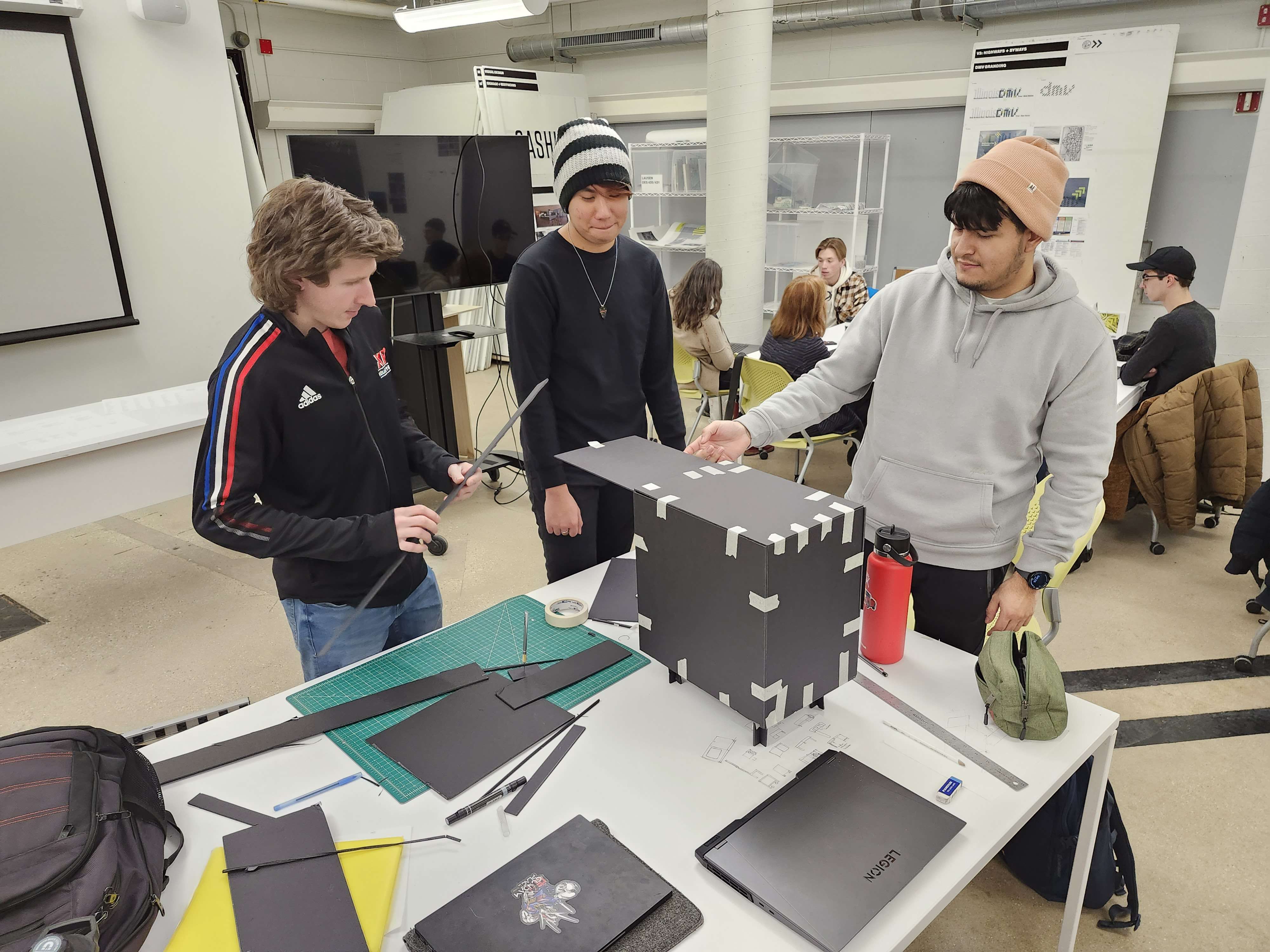

Physical prototyping started with foam board, then continued with foam core. We first wanted to experience how the size felt. We started by making a 1:2 scale model of our first iteration. This scale model included legs on the sliding workspaces to hold up them up.

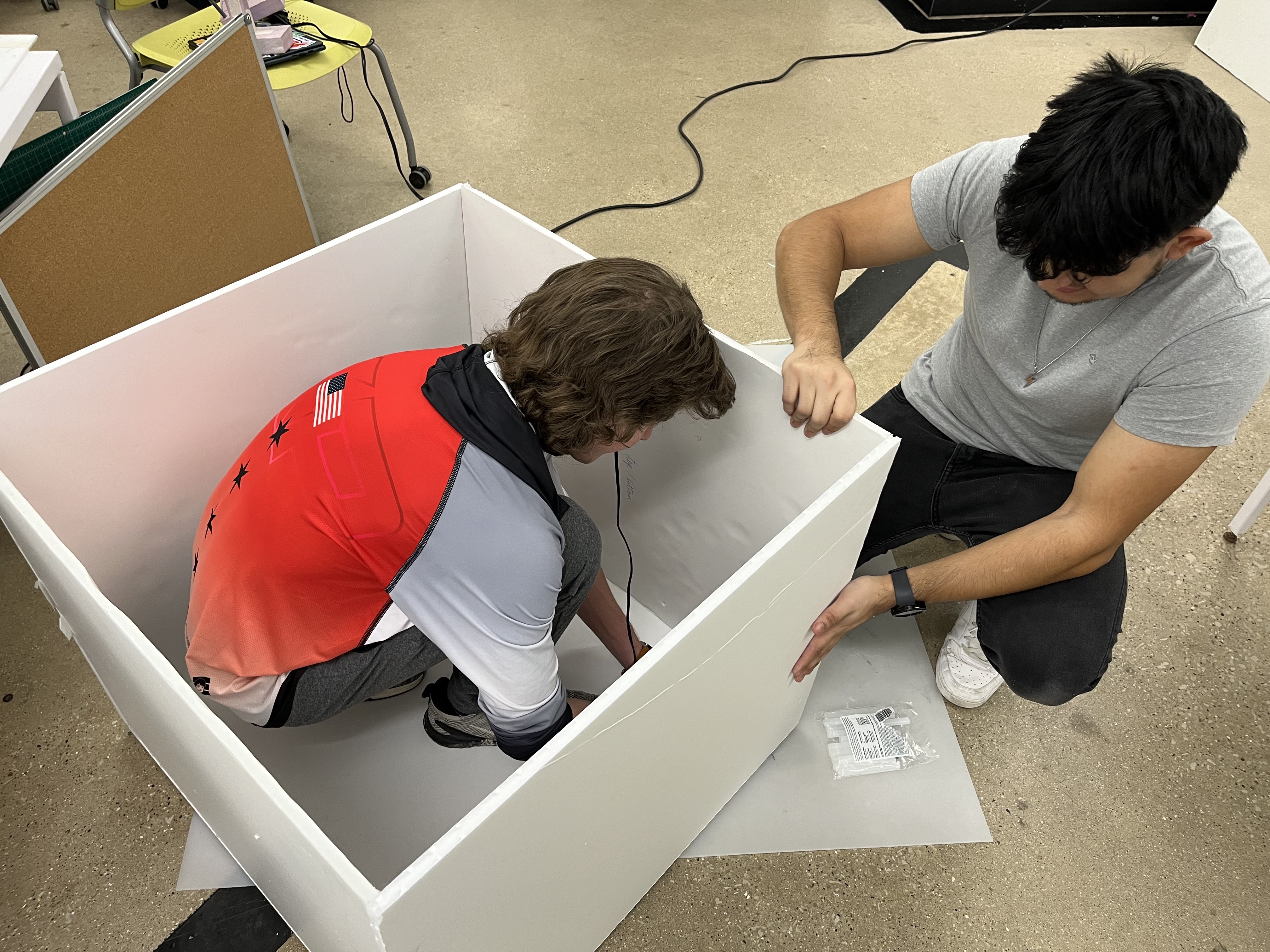

When we felt satisfied with the layout of the 1:2 scale model, we decided to model a 1:1 model of the cart from foam core.

It was also necessary that we tested the sizing of our model with an average sized elevator.

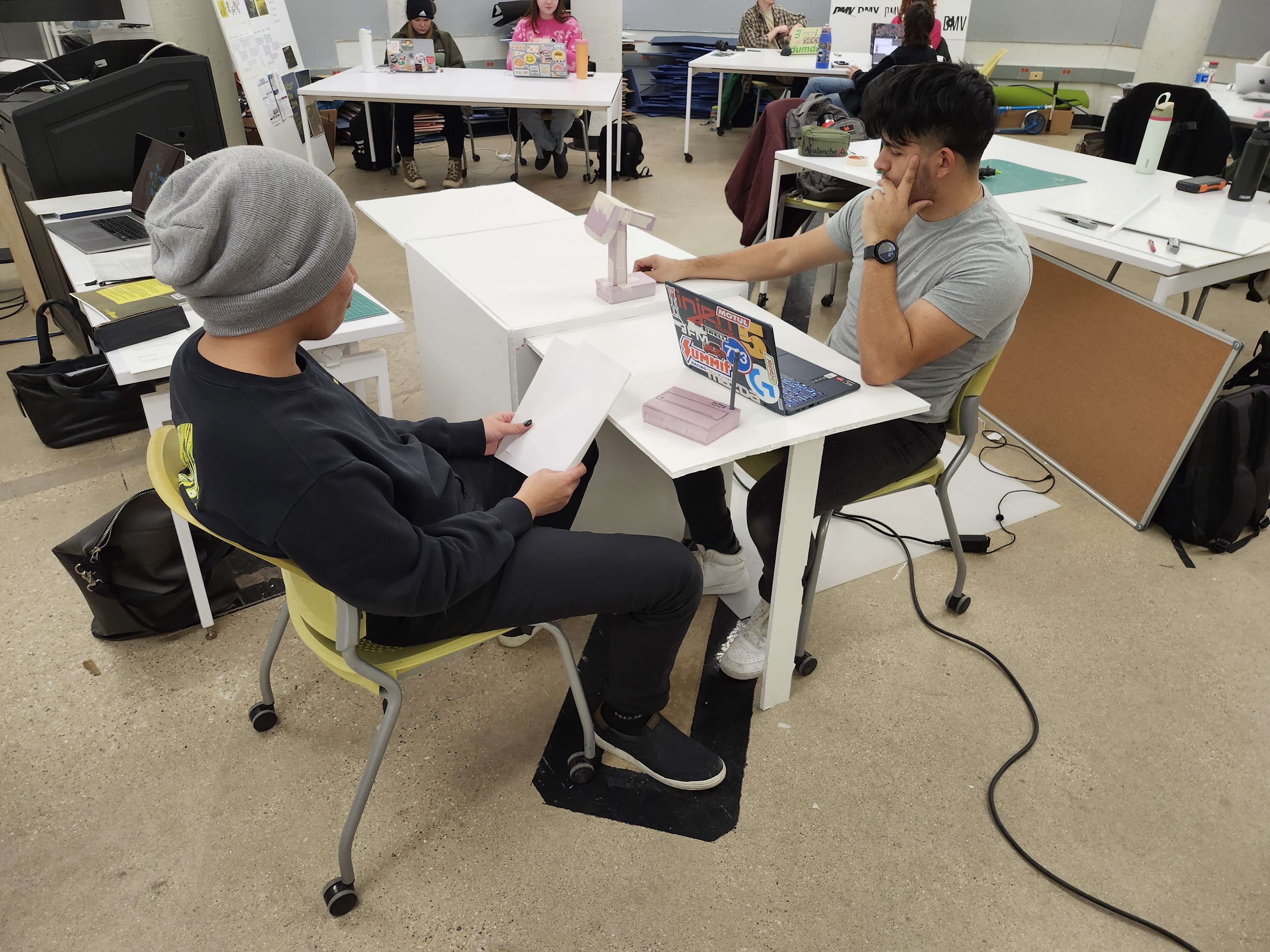

Our foam core prototype and testing with the other design students, including graphic designers, revealed a few points to us. Firstly, the sizing was nearly there, but the workspace needed a small adjustment, by increasing the depth of the workspace but reducing the width. Secondly, the sliding workspaces forced us to use an uneven layout for them, one being taller than the other, which at first seemed unique, yet still effective. While it wasn’t detrimental to the design, it was less practical than we expected. Added to this, we weren’t quite sure anymore how well the sliding workspaces would hold under constant weight and movement, especially without a leg support.